I decided to include this page on my website because building my own house was one of the biggest accomplishments in my life. And of course, we did also install the plumbing in it too.

I was fortunate to purchase my land when I was at a very young age. I think I was around 18 or 19 years old. It was still expensive back then, but land was much more affordable than it is now. Me and my older brother bought 10 acres of land together next to my parents’ 5 acres of property. We had previously built my parents’ house there in 1988.

I wanted my house to be in a secluded location. So me and my brother split up our 10 acres with mine being farther away from the road. I liked this land because it had a lot of hardwood trees on it, and it had a creek crossing it too. It was also nice that it’s only about a mile from interstate I-20. One of the lumber delivery drivers liked to refer to it as “the house in the woods” later when we were building the house.

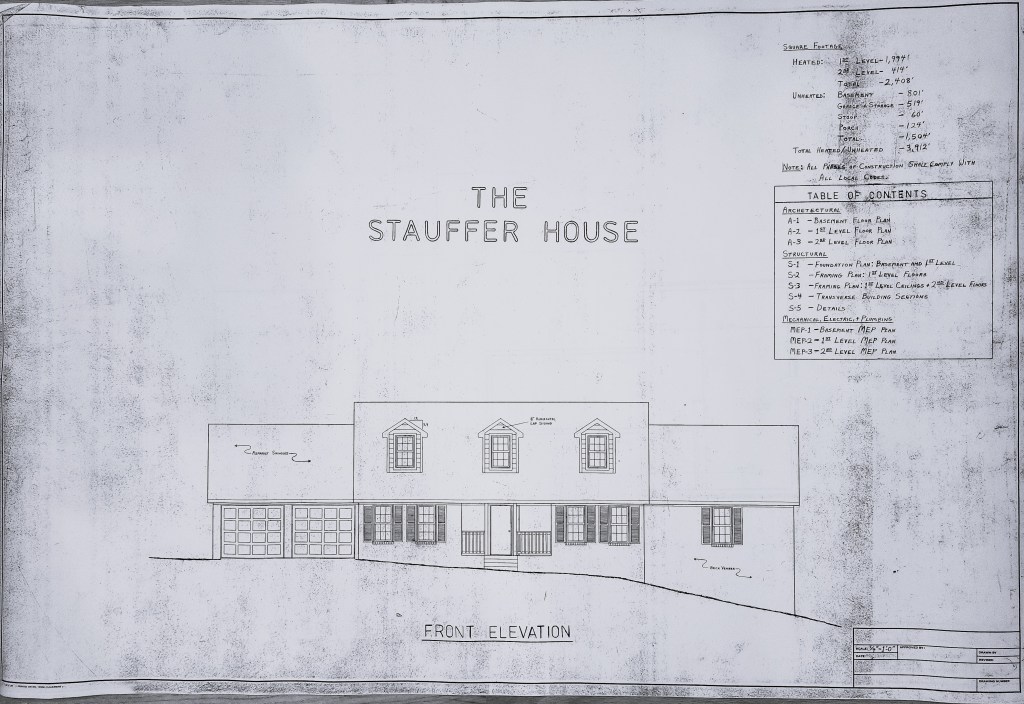

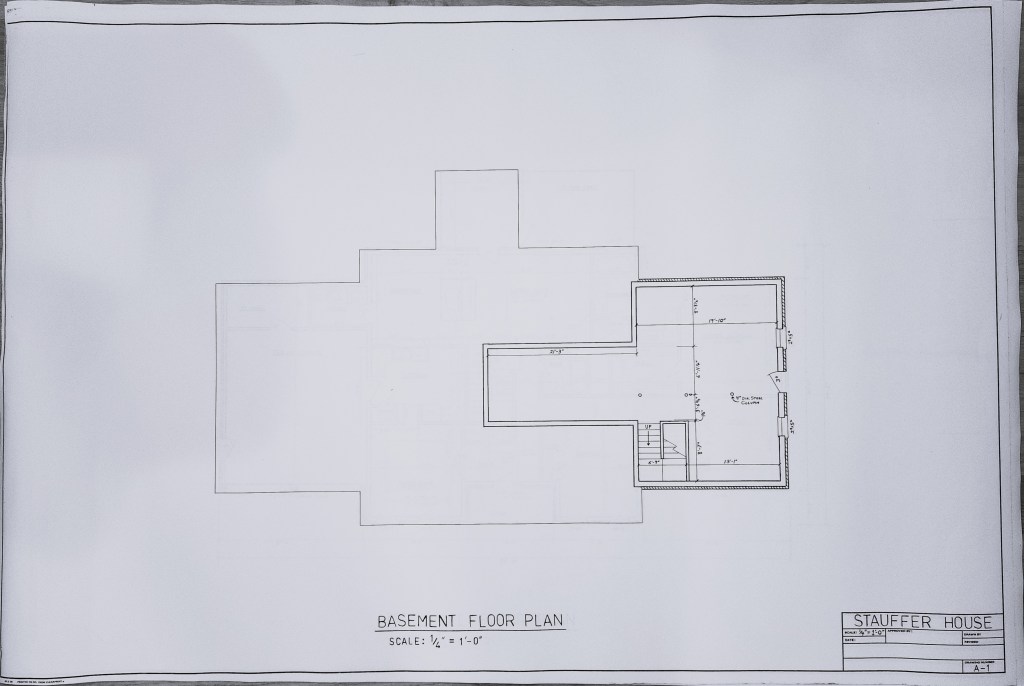

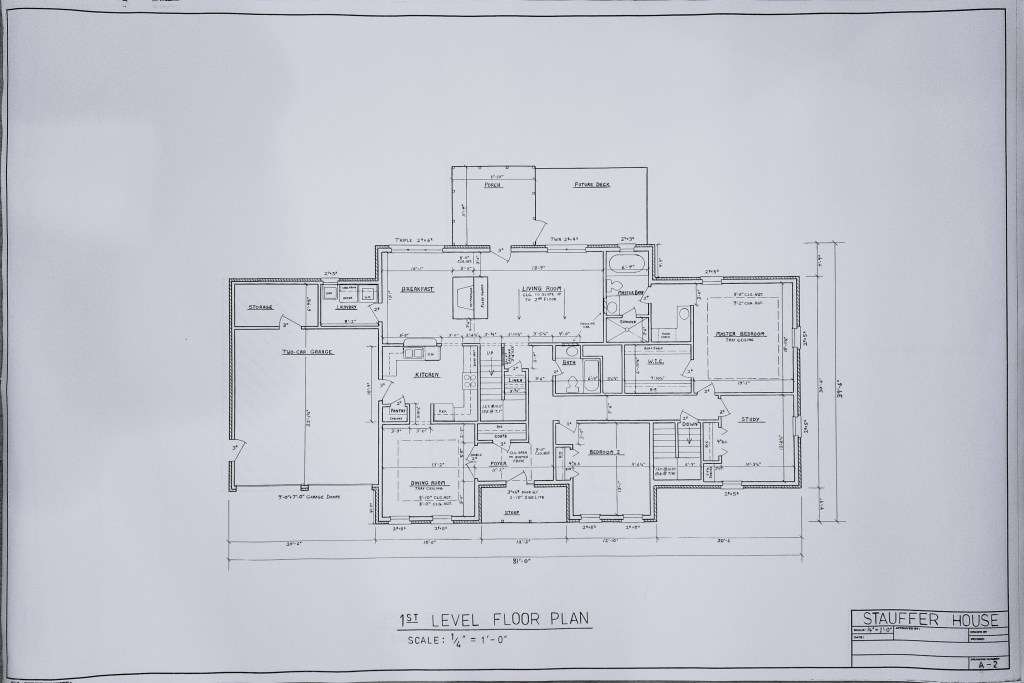

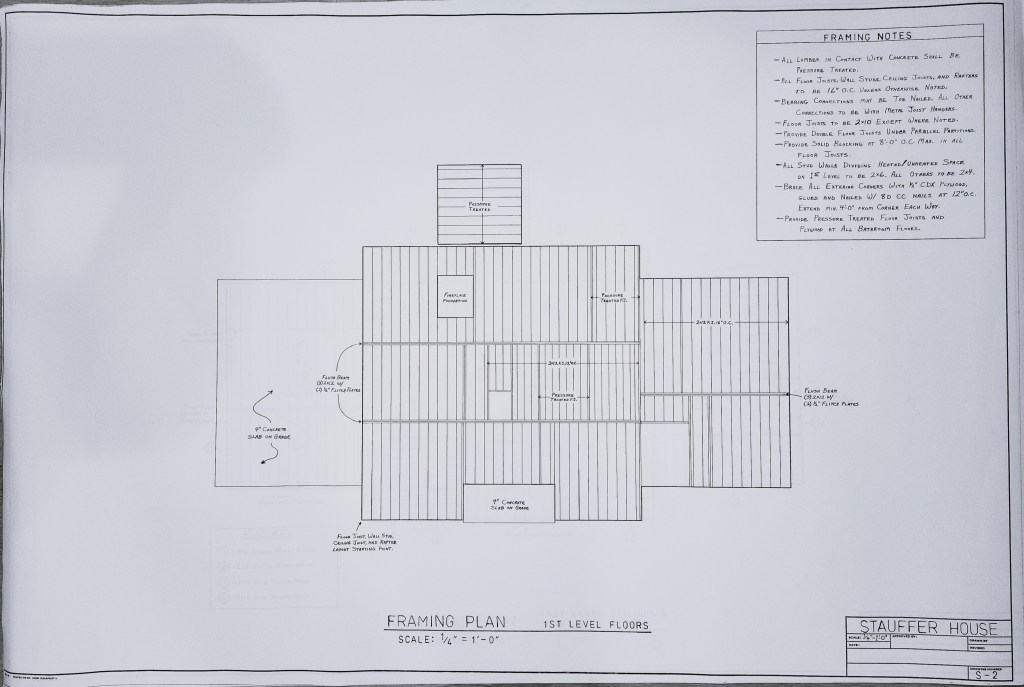

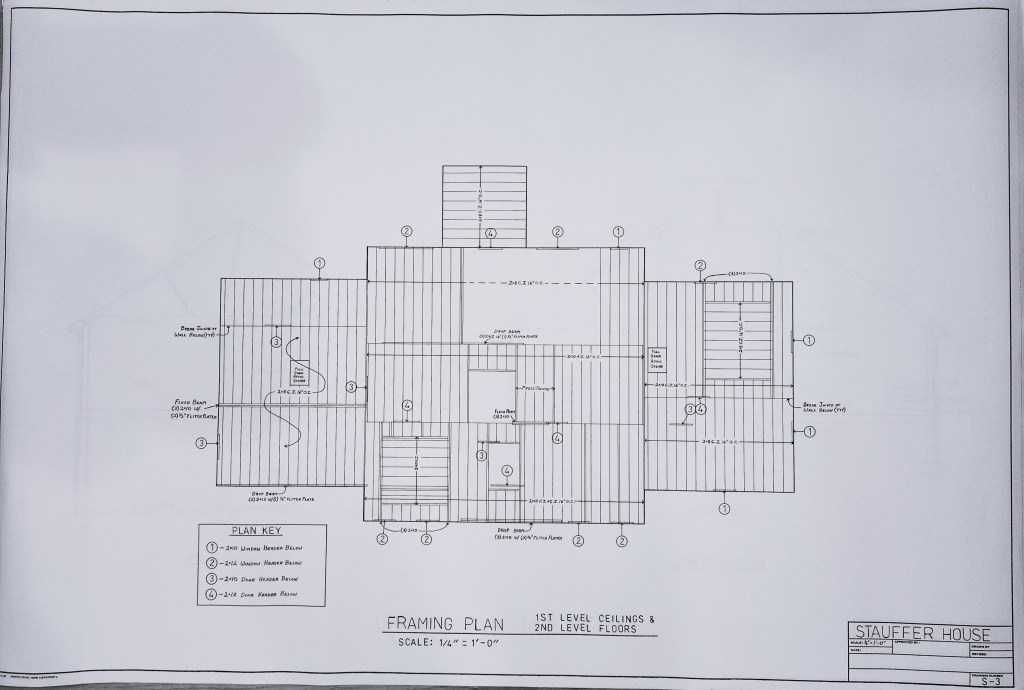

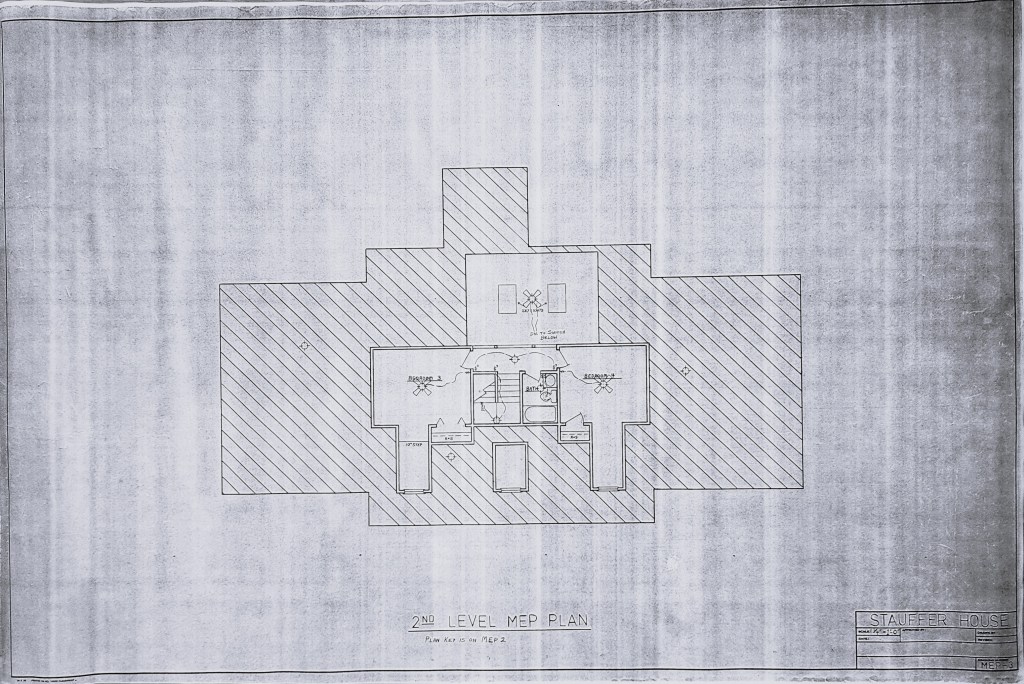

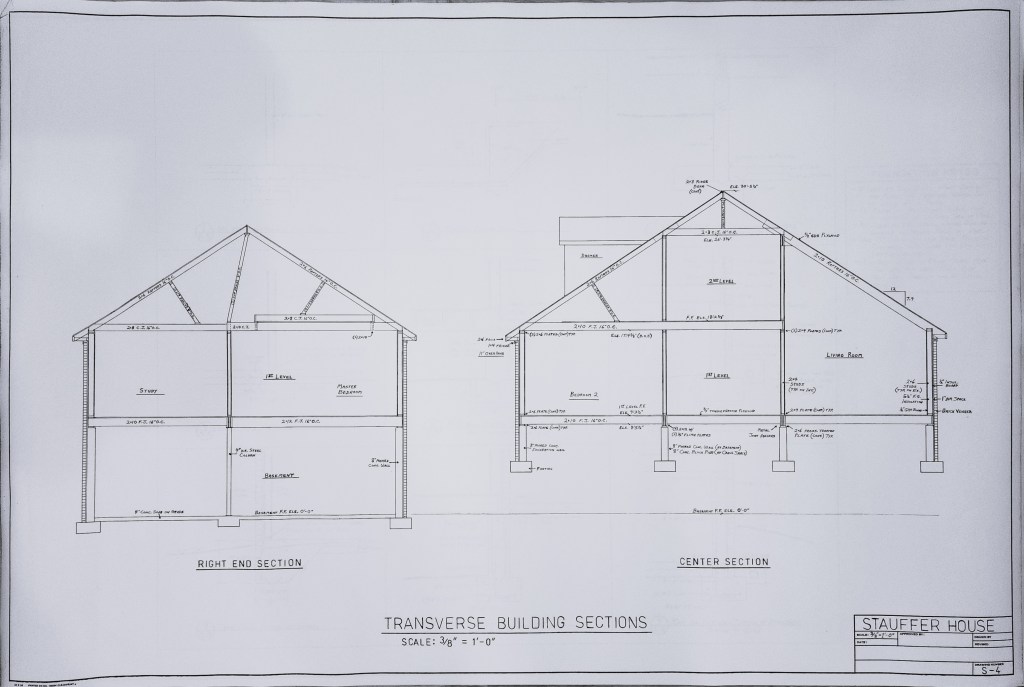

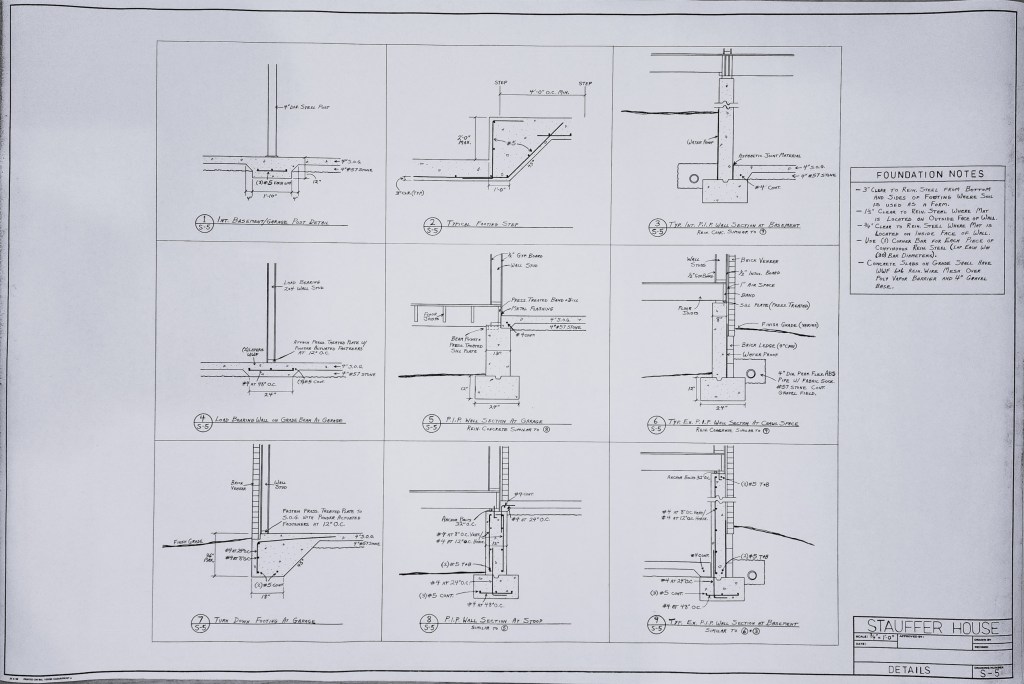

In my mid to late 20’s, I started drawing up plans for the house that we would build. I tried to draw up the plans to look as professional as I could. I needed to take out a construction loan for financing, and I didn’t know if the bank would require an architect to draw up the plans. I wanted to avoid having to hire an architect. As it turned out, the bank did accept my drawings. I drew the drawings by hand since CAD wasn’t really available back then. Even some architects were still making their own drawings by hand at that time. These are the drawings that I made:

I worked all of the overtime and side work that I could in my mid to late twenties to save up $25,000 to start the construction of the house. Back then, that was a fair amount of money. It was enough to get the septic system installed and to complete much of the foundation and slabs. We started the actual construction of the house in early 1997, when I was just 29 years old. I already had one young child when my wife became pregnant with our 2nd child during construction. We worked on the house every day after work, and on Saturdays and Sundays too. It was a very challenging period of my life for me.

I did have some people that were very helpful to me. I generally paid a minimal amount ($10/hr.) when people came out to help, in addition to always providing lunch. Even though they were getting paid, I still felt like they were doing me a favor since they were willing to work for that cheap. 12 of my coworkers from Stasco Mechanical came out to help during the course of construction. And of all of the people whose help I appreciated, I have to give the largest amount of gratitude to Joe Lenox and my older brother Konrad. Both of them were there pretty much every day. I didn’t pay my brother for his work either. But I did help him to build his house in 2017 in return. Those pictures can be seen here: Building my brother’s house (2016 to 2017).

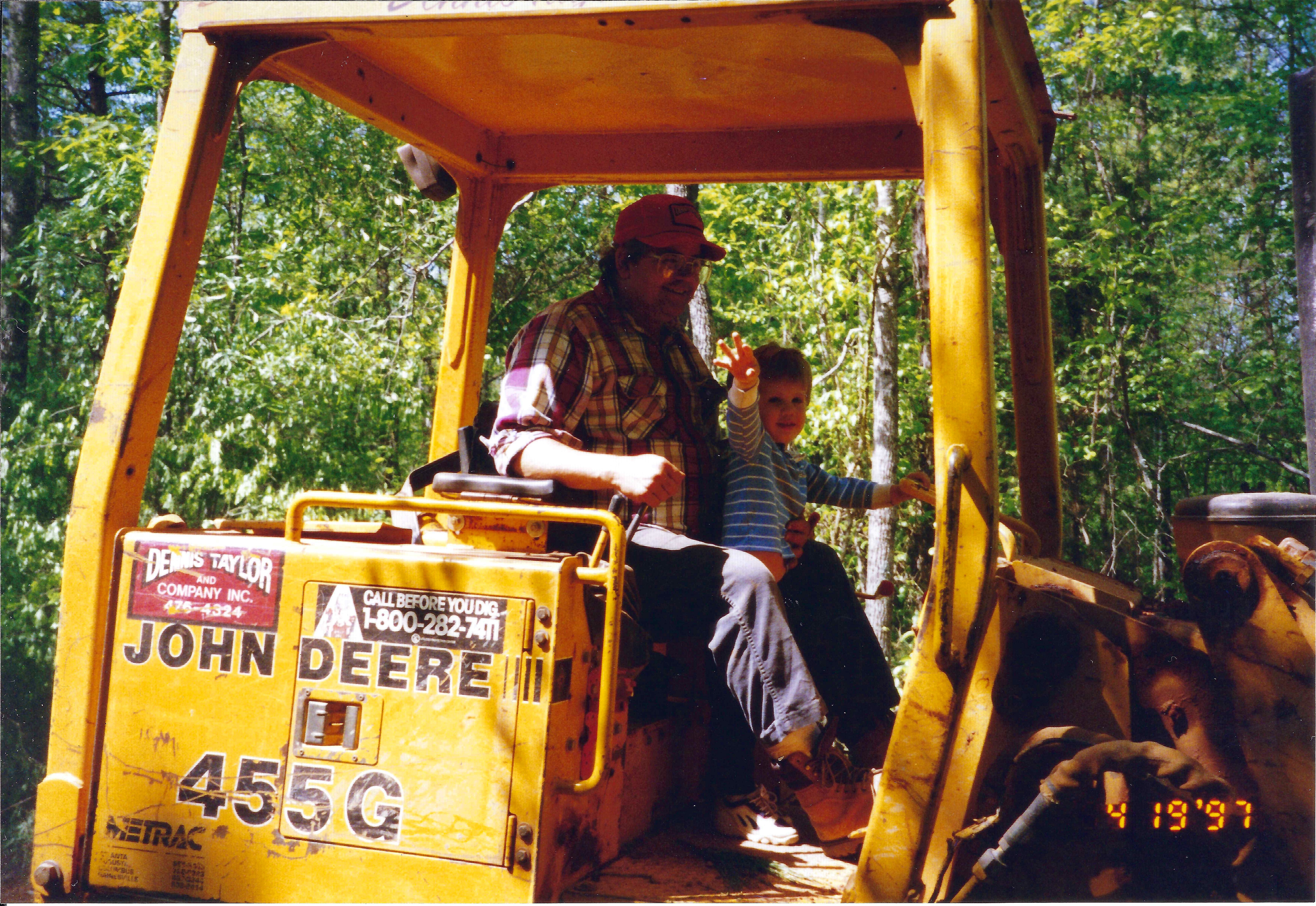

I also very much appreciate my employer, Stasco Mechanical, for loaning me a backhoe a couple of times and for giving me the material and fixtures for the plumbing. I also appreciate my Dad’s employer, Dennis Taylor, for sending out tractors multiple times for us to use. I’m not sure how many thousands of dollars these favors saved me, but I’m sure that it definitely was quite a few.

The following pictures are film pictures that I took during construction.

(Click on images to enlarge)

Building the 1,000 foot long driveway:

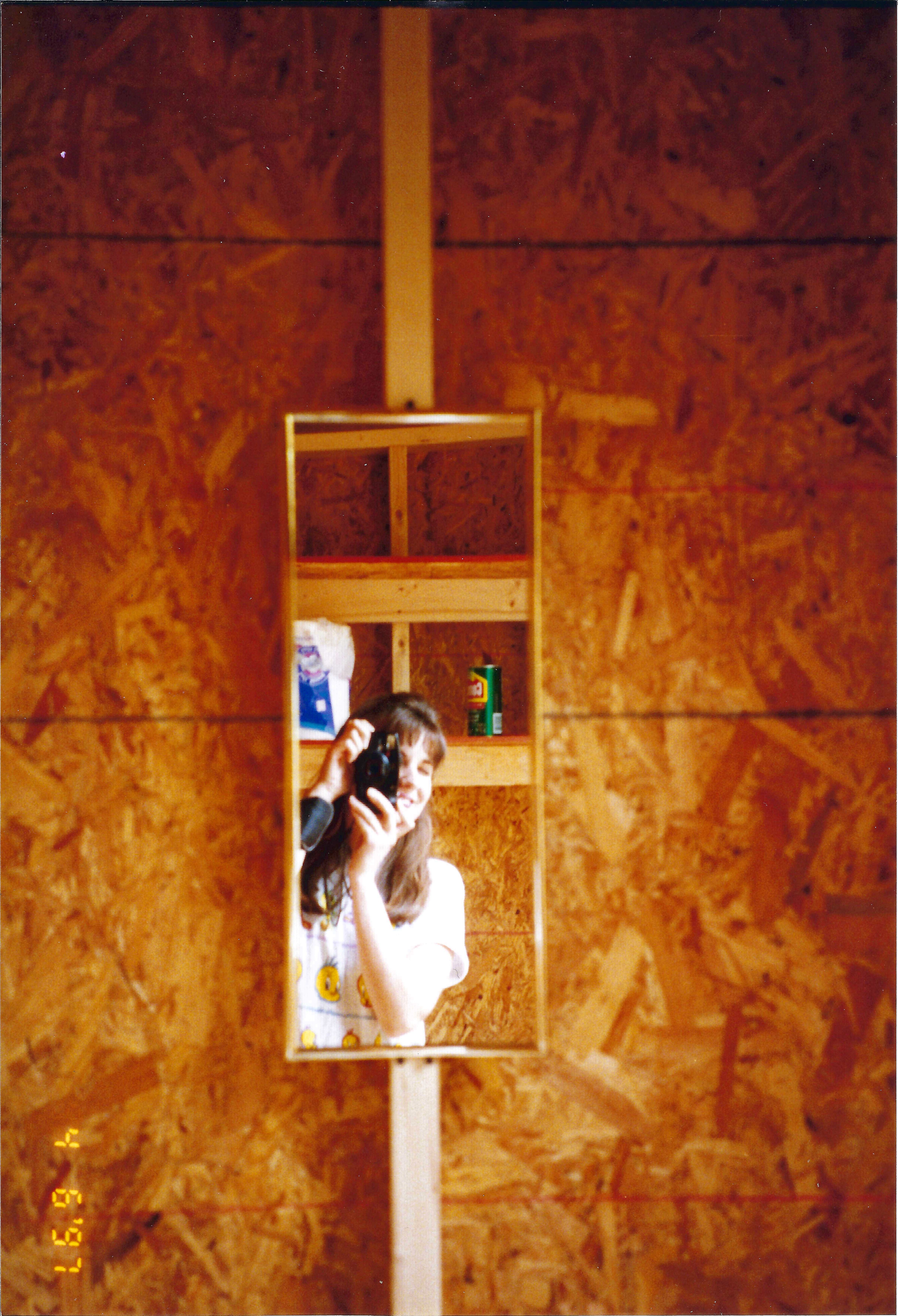

Power is installed, and we built a storage shed to store tools and stuff during construction. I bought an air compressor and a nail gun to assist in the framing while building the house:

We built an outhouse right on top of the septic tank that had already been installed to have the convenience of having somewhere to use the bathroom:

I had selected the house site partially because I liked this huge, old beech tree so much, having it centered behind the house. Unfortunately, the tree fell about 10 years later:

Building the house pad:

Constructing the basement footings:

Two carpenters that worked for Winter Construction came out to help us build the concrete walls for the basement. Their names were Wilson and Preston. I don’t remember their last names. My Dad was able to get all of the rebar for the house from his work for free.

My Dad was also able to get some commercial style waterproofing material from his work for free.

In these pictures, we are constructing the rest of the footings. Me and my Dad had gotten into an argument, and he refused to come help for a short period of time. Long time Stasco foremen, Taze Latham and Ben Fouts, each came out for a day to dig footings for us. Neither one of them would accept any money for their work though. Unfortunately, I didn’t get any pictures of Ben. Taze and Ben have both passed away since then.

While installing the sewer line, we hit and broke the underground power line. The power company originally wanted to charge me for the repair. But I showed them the pictures of it being only 2 feet deep. It was supposed to be buried 4 feet deep. They apparently went very shallow at this location because of all of the rock, even though they had previously charged me for blasting the rock. We had to use multiple offsets on the sewer line to weave in between the rock. I didn’t like having all of those additional offsets, but I’ve never had any problem with the sewer in the 27+ years that I’ve lived here.

We ran underground storm drainage piping for all of the gutter downspouts. All of the rain water drainage is piped far away and downhill from the house.

One of my neighbors at that time was Dwight Luke. He worked for himself doing concrete work and laying brick/block. Dwight and his crew laid most of the block (we did some), poured all of the concrete, and laid all of the brick.

We are prepping the basement slab in these pictures. We had originally roughed in the drainage piping for a future bathroom in the basement, but the plumbing inspector turned us down because he said the pipe was too shallow. He said that the pipe needed to have some cover. I’ve never heard something like that before, considering that we frequently have situations in commercial plumbing where portions of drainage piping sometimes wind up being totally encased in concrete. So we did cut out the drainage piping for the inspection. But I still left it stubbed into the basement for future use. It’s probably a good thing that the inspector did turn us down since I wound up going with a different wall layout several years later when I finished the basement. Ironically, that one plumbing inspection is the only inspection that we failed out of all of the inspections throughout the project.

In these pictures, we are prepping and pouring the garage slab. I put a floor drain in the garage that I’ve never wound up needing in the 27+ years of living here. I also ran an extra conduit from the power entrance point to the basement for future use. I did wind up using that later for electrical wiring when I finished the basement.

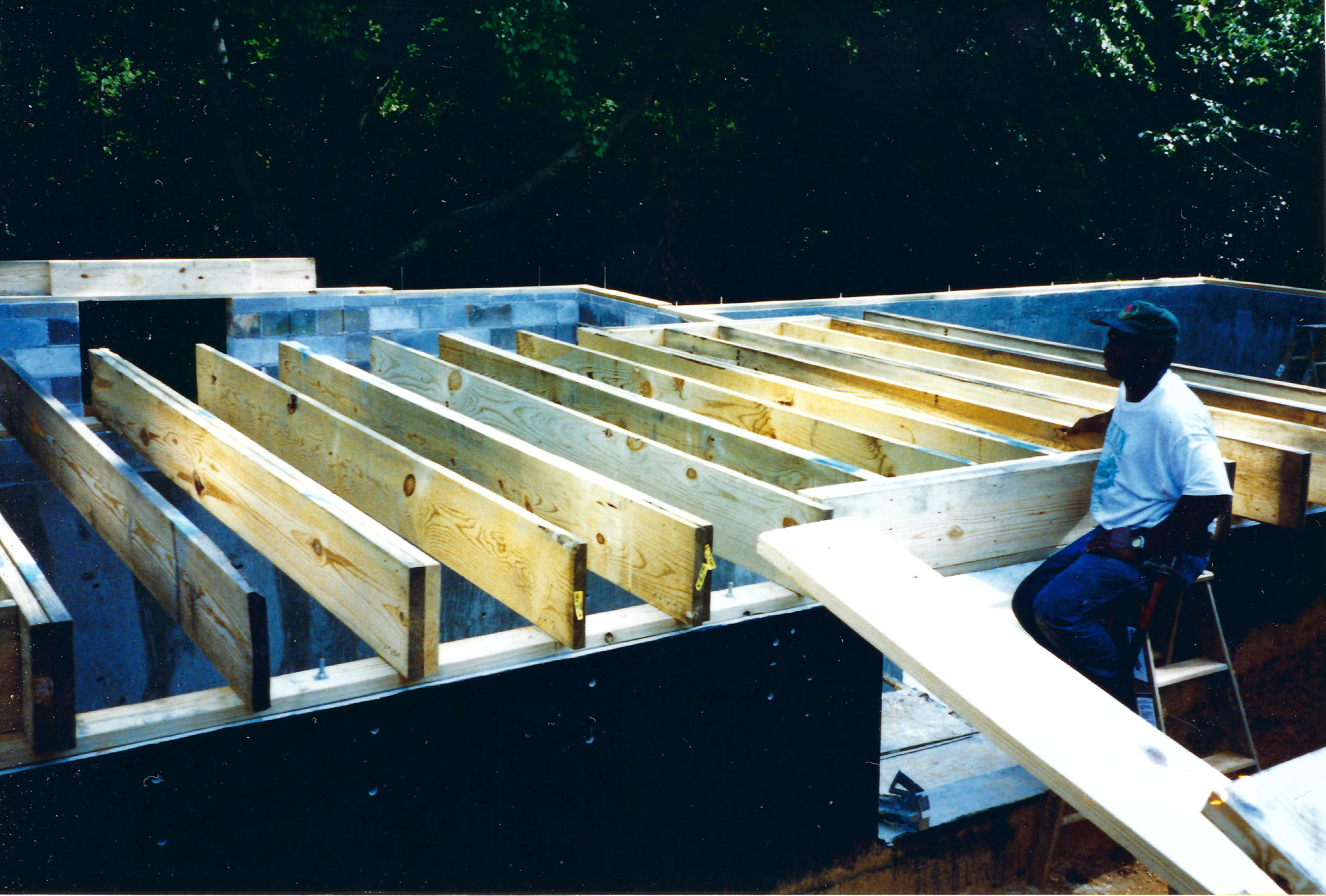

With the foundation complete, we were ready to begin framing. I got those two large, steel I-beams for free from the Gasket City Lofts job that I was doing at that time. A Winter Construction employee named Leroy delivered them to me for free using a Winter dump truck. I can’t remember Leroy’s last name. We made sure to get the crawl space dirt leveled out really well, with plenty of clearance to the floor joists. Denis Wanco also spread plastic sheathing on the ground for me at a later date. I wanted to be sure that I had a nice crawlspace after having been in so many crappy ones over the years.

In framing the main level floor, I beefed up the area over the thin part of the basement to have a good storm shelter underneath. We used 2 x 12’s for the span, even though it wasn’t very long. In addition, we doubled them up at every other joist location. My Dad and brother built the steel columns from 4″ schedule 40 steel pipe that we already had.

We are decking the main level floor in these pictures. One of the extra things that I chose to do is to use pressure treated marine plywood for all of the bathroom and kitchen floors. I had sometimes seen rotted floors when doing side work on some of the old houses that I’ve worked on. I wanted to take that extra step to prevent any future rot.

We are framing the main level walls in these pictures. On all of the exterior walls, I chose to use 2 x 6 studs for added strength and thicker wall insulation. I also liked the idea of having wider window sills. Also, right when we first started framing the walls, Joe Lenox accidentally shot and nicked his finger with a nail from the nail gun. That made me wonder if we were trying to take on too much.

My dad and brother built both of the stairways. My Dad would get aggravated with me because we only had one nail gun. They had to use hammers on the stairs.

We are framing and decking the main level ceilings/2nd level floor in these pictures. One of the good things that I was able to do is to use all of the 3/4″ form plywood that was left over from forming the basement walls to floor the entire attic. We have a huge amount of usable attic space.

We are framing the roof in these pictures. I chose to stick frame it instead of using prefabricated roof trusses because I wanted to have plenty of usable attic space for storage. I hate having to climb through all of the bracing on prefabricated roof trusses.

We are sheathing the roof in these pictures. I had planned on installing the felt paper ourselves. But the roof wound up being so steep that I really didn’t feel comfortable doing it. So we let the roofers do it instead.

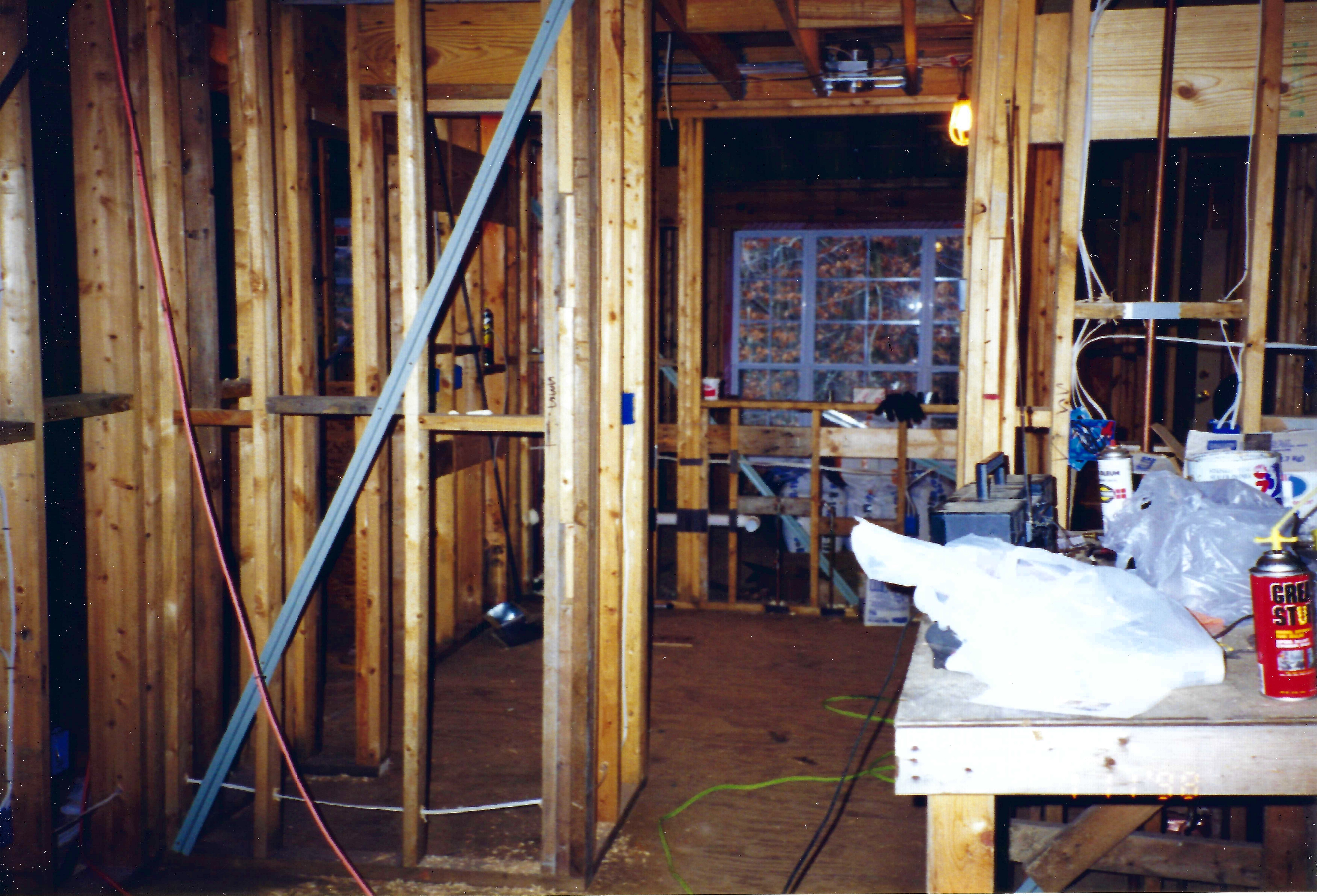

These are some miscellaneous interior framing pictures:

The roof shingles are getting installed in these pictures. Shawn Jenkins (Stasco employee) and his buddies did the installation. We did assist them, mainly by helping to carry the shingles up to the roof. During the roofing, one of Shawn’s buddies accidentally shot himself in the leg with a roofing nail gun. He kept on working though.

Installing the house wrap:

Hardie plank siding wasn’t really being used as predominantly back then. If I remember right, it was still relatively new. I would definitely have preferred to use it if it hadn’t been so new. Instead, I used vinyl siding. I wanted the exterior to be as maintenance free as possible. Bill and his wife (both Stasco employees – I don’t remember their last name) started the vinyl siding. They were the only people that let me down during the entire project. I couldn’t get Bill to come finish the job. I wound up having to hire a company to come and finish the installation, which probably cost me additional money.

Brick installation:

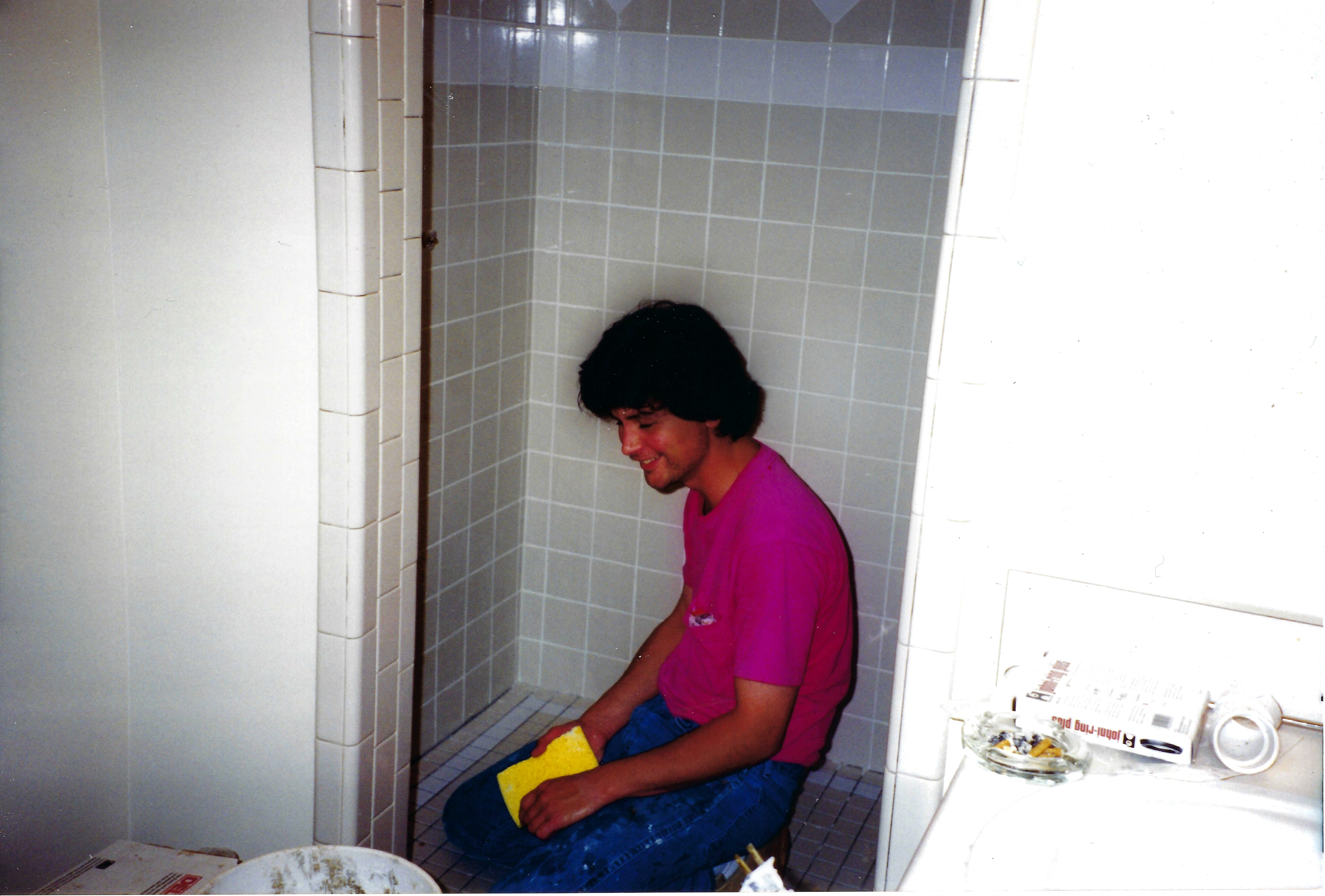

These are some miscellaneous interior pictures. On the plumbing, we pretty much ran two cold water mains in the house. One of the mains was reduced pressure for the plumbing fixtures. And the other main was full pressure (about 95 lbs.) that served the 4 hose bibbs around the house and the partial fire sprinkler system that we installed.

We are installing the insulation in these pictures. We also insulated the floor of the 2nd level in the hopes of soundproofing it. I’m not sure how much it helped though.

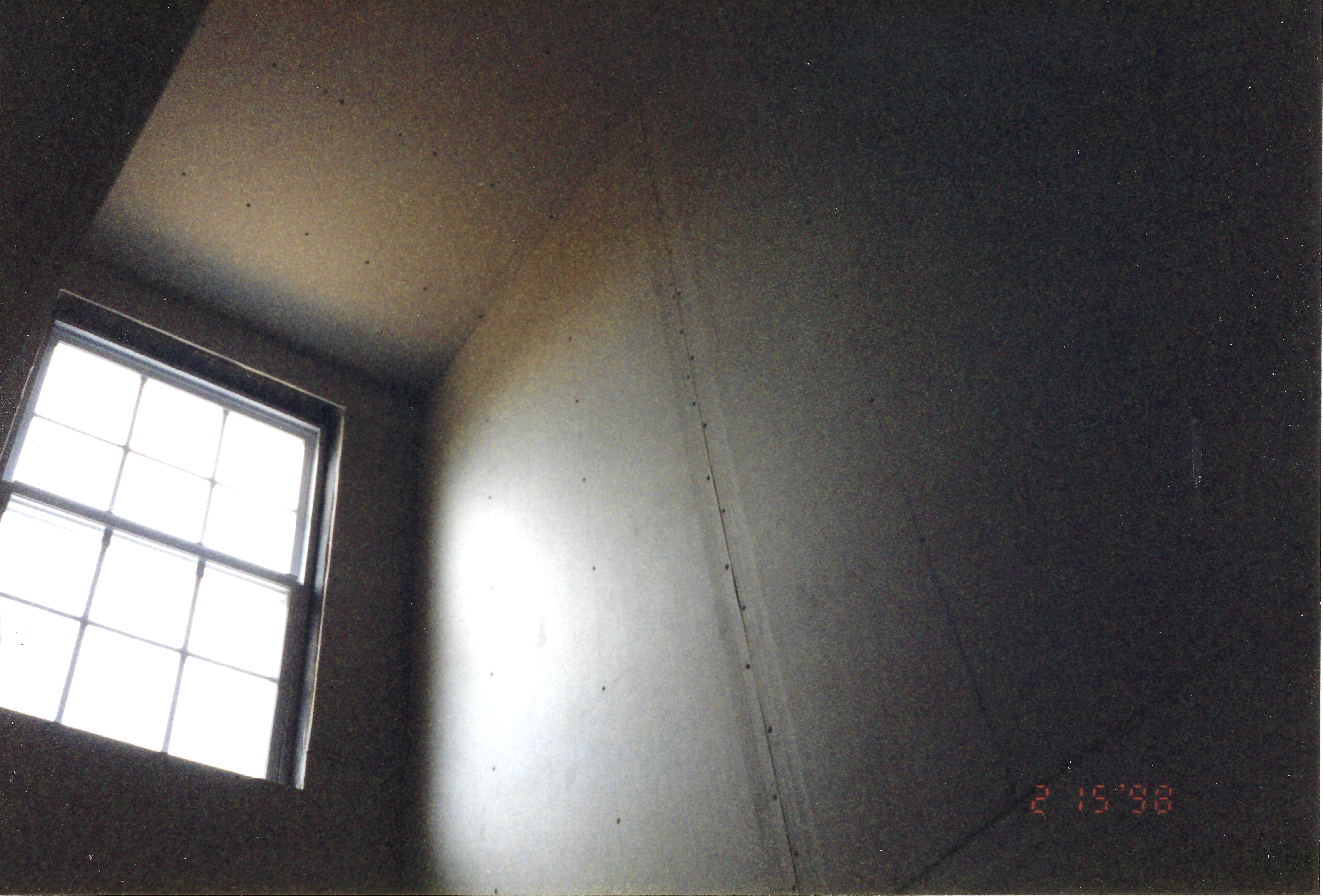

Installing sheetrock:

Installing the hardwood floors:

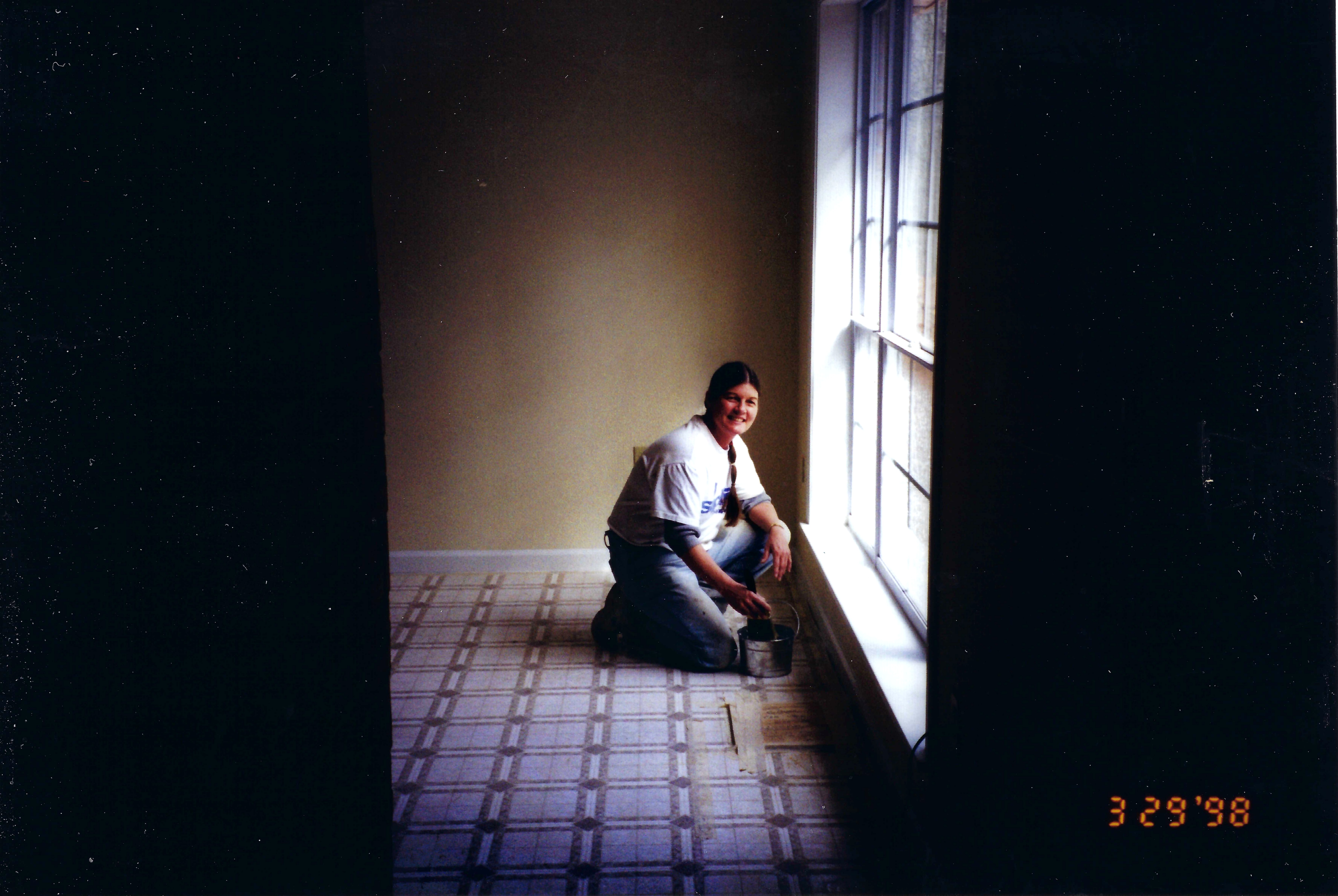

Painting:

Miscellaneous pictures:

We performed most of the work ourselves in the construction of my house. But I did have to hire a few contractors to do some of the work.

I hired people/companies to do the following things in building my house:

- Install the septic system (Douglas county required this)

- Pour and finish the concrete

- Treat the slabs with pesticides

- Install the block (we did install some)

- Install the brick

- Install the vinyl siding

- Install the fireplace

- Install the HVAC systems (though we did run the line sets and condensate lines)

- Finish the sheetrock

- Finish the hardwood floors

- Install the carpet and linoleum

- Install the garage doors (Joe Lenox’s brother did this)

Work that I hired an expert(s) for that we helped with the installation:

- Build the concrete basement walls

- Install the roofing

- Install the electrical

Work that was performed completely by ourselves:

- Clear the land, construct the driveway, and level/excavate the house pad

- Ran the water, telephone, and cable services up my 1,000′ long driveway

- Lay out the house, and dig and/or form footings and slab edges

- Prep the slabs

- Waterproof the basement walls

- Frame the house

- Install the house wrap and the exterior doors and windows

- Install the plumbing

- Install the insulation

- Install the sheetrock

- Install the interior doors and trim

- Install the hardwood floors

- Install and grout the tile

- Install the cabinets

- Paint

- Final grading and seeding the lawn

- Plus other miscellaneous things that GC’s typically do

I would also like to add that I am very grateful to Jerry Johnson (former Shumate sub) for installing both of my HVAC systems and only charging me for the cost of the equipment. He supplied the labor, ductwork material, and the lineset material to me for free. I was supposed to pay him back with a plumbing installation in the future, but he never called back. And 27+ years have passed by now.

The following people that helped build the house were either current or former Stasco employees at that time. My guess for their length of service to Stasco is in parenthesis.

- Joe Lenox (14 – 16 years)

- Konrad Stauffer – my brother (3 months)

- Denis Wanco (6 – 8 years)

- Shawn Jenkins (5 – 8 years)

- Taze Latham (40 -50 years)

- Ben Fouts (35 – 45 years)

- A couple of guys that helped on the framing – I don’t remember their names (short term)

- Bill and his wife – vinyl siding (6 to 12 months)

- Louann Bureau (8 – 10 years)

- Kenny Grover (25 years)

- And of course, me (32 years)

- I apologize if I missed anybody.

I also want to mention that Ben Fouts, Taze Latham, and Denis Wanco sadly have all passed away since then.

I would also like to acknowledge:

- Paul York (15 – 20 years?): For giving me the go ahead to use material from Stasco for the plumbing installation, without me even asking.

- Wes Eardley (Vice president of Stasco – 30 – 40 years): Priced out and located the 1,000′ of water service material and the Whirlpool bathtub for the master bath for me.

- Allen Hall (20+ years?): Gave me some culvert pipe that he had for my driveway.

I learned that building your own house is a huge amount of work. And I can’t say that it would be a good thing for just anybody to do. But I do think that I saw the following benefits from us doing it ourselves:

- Save some money by self-performing the work. I’m not sure how much money is saved though. And I’m not entirely sure that it’s worth doing it just for this one bullet point alone.

- Ensure that quality work is performed and everything is done right.

- Make changes at minimal cost as compared to making changes through GC’s and subcontractors.

- Not having to worry about the reliability of other people doing their work in a timely fashion (i.e. the original vinyl siding crew that I hired).

And speaking of making changes, I did make a few spontaneous changes from the drawings when we were building the house. We shifted the coat closet in the foyer to the right side of the front door, shifted the exterior garage door more towards the rear of the house, turned the toilet in the hall bath on the main level towards the tub, added an exterior door and a private deck off of the master bedroom, and eliminated the closets for the bedrooms on the 2nd floor (assuming that I could build them later, saving some money at the time). But that was pretty much the extent of the changes that we made. Everything else is built exactly as it’s drawn.

Some of my observations on how some things would have been so much easier if we’d have had some of the technology that we have today:

- Designing the house and creating the drawings would have been so much easier if computers had been a little more advanced.

- Researching and learning about different materials available and installation techniques would have been so much easier if the internet, Google, and YouTube were available back then.

- .Cordless power tools are easier and more convenient to use, but weren’t really available back then.

- Having a laser level back then would have been awesome! We had to use levels and plumb bobs for everything instead.

Finishing my basement (2000)

I finished the basement in 2000 so that my mother-in-law and sister-in-law could move in with us. I did most of the work by myself, without asking anybody to come help. I can’t remember for sure, but I think that Joe Lenox might have come over to help me hang some sheetrock. I just can’t remember. I did hire an electrician (Eddie from Askay), an HVAC mechanic, a sheetrock finisher, and a flooring installer to help with the job.

I didn’t take very many pictures though. These are the ones that I did take:

I built 2 bedrooms, a living room, a kitchen with a dining area, a laundry room, and a bathroom in the basement.

After finishing the basement, it added 800 square feet of heated space to the house, for a total of 3,200 square feet. The house now had a total of 7 bedrooms, 4 bathrooms, 2 kitchens, and 2 laundry rooms. That does seem like a lot, but it was pretty comfortable for the 7 people (Me, my wife, my 3 kids, my mother-in-law, and my sister-in-law) that lived here for quite a few years. As time moved on though, the number of people living here has shrunk a pretty good bit with my wife divorcing me, my oldest son getting married and moving out, my sister-in-law getting married and moving out, and my mother-in-law moving out to live with my sister-in-law as her health declined. Now there’s just the 3 of us living in the house with my middle son also wanting to get a place of his own. I realize now that the house is much bigger than what I’ll need for my remaining years. But oh well. It did work out pretty good as the family house that I envisioned when I was designing it as a young man. I am planning to live here until I die, with no desire to go live anywhere else. Thank you to everybody that helped me!